How to Choose the Right Stainless Hexagon Bar for Your Project?

When it comes to selecting a Stainless Hexagon Bar, the choices can be overwhelming. Industry expert John Smith noted, "Choosing the right stainless hexagon bar can make or break your project." This emphasizes the importance of making informed decisions.

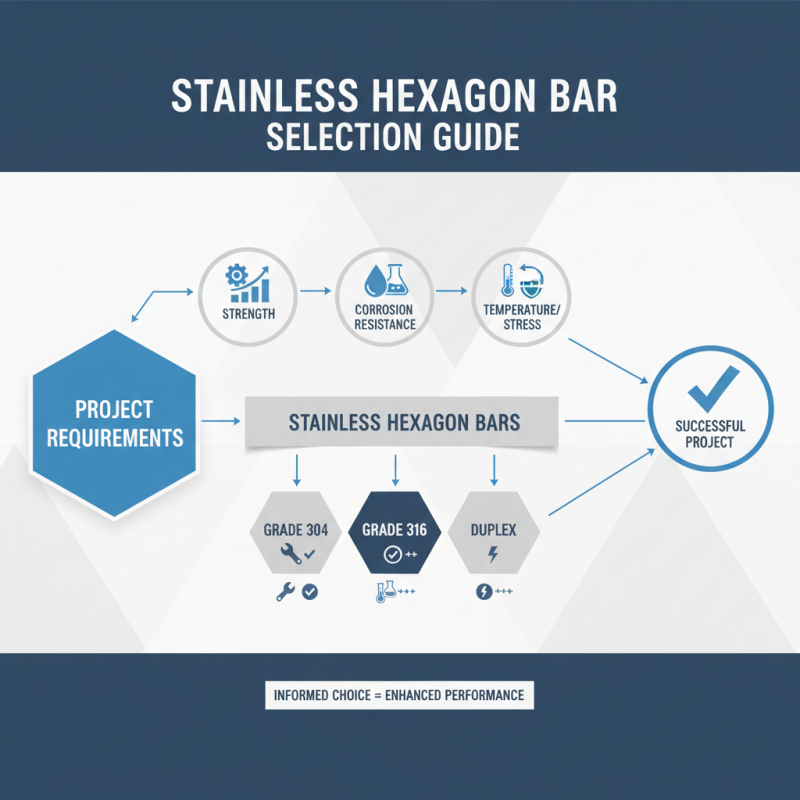

Stainless Hexagon Bars are versatile and used in various applications. They offer strength and resistance to corrosion. However, selecting the correct size and grade is crucial. Not all bars are created equal, and small details can impact performance.

Consider your project's unique needs. Some bars may look similar but behave differently under stress or temperature shifts. It’s essential to ask questions and reflect on your requirements. A thoughtful choice of Stainless Hexagon Bar can significantly enhance your project's success.

Understanding the Basics of Stainless Hexagon Bars

When selecting a stainless hexagon bar, understanding its basics is essential. Stainless hexagon bars come in various grades, each with unique properties. Grade 304, for instance, is widely used due to its corrosion resistance, while grade 316 offers better durability in harsher environments. Knowing these differences can guide your choice effectively.

Tip: Always consider the environment where the hexagon bar will be used. For outdoor applications, a higher corrosion-resistant grade will save future costs.

Choosing the right size is also critical. Measure the required dimensions accurately. A common mistake is assuming that one size fits all. Oversizing can lead to unnecessary weight, while undersizing may compromise strength. This requires careful thought.

Tip: Keep a detailed list of your project’s specifications. This checklist can help to avoid errors during selection.

Moreover, aesthetics may play a role depending on your project. The polished finish can enhance appearance but may come at a higher cost. Balancing appearance and function is key. Reflect on your project needs; sometimes, it's okay to go for a less shiny option if it serves the purpose well.

Identifying Different Grades of Stainless Steel

When selecting a stainless hexagon bar, understanding different grades of stainless steel is crucial. There are several common grades, each with unique properties. Grade 304 stainless steel is one of the most widely used types. It offers high corrosion resistance and good weldability, making it versatile for many projects.

Another important grade is 316 stainless steel. This grade contains molybdenum, which enhances its resistance to corrosion, especially in harsh marine environments. According to the Stainless Steel Information Center, 316 grade is often recommended for applications exposed to saltwater. It's essential to consider the specific needs of your project when choosing between these grades.

However, not all projects require high-end material. Sometimes, lower grades may suffice. For instance, in non-corrosive environments, 430 stainless steel could be an option. It’s affordable and still performs well in certain applications. Yet, overlooking the environment's potential impacts can lead to premature failure. Evaluating the environment and intended use carefully is key to making the right choice.

Stainless Steel Hexagon Bar Grades Comparison

Assessing the Dimensions and Tolerances Required for Your Project

When selecting a stainless hexagon bar, assessing dimensions is crucial. Measurements must precisely match project requirements. Tolerances can significantly impact the performance of the final product. According to industry reports, a typical tolerance range for stainless hexagon bars can be ±0.5 mm for diameters under 25 mm. This may lead to discrepancies during machining processes, emphasizing the need for accurate specifications.

Material thickness is another important factor. Thin bars can be less robust, risking structural integrity. Conversely, overly thick bars may lead to unnecessary weight and cost. A careful examination of stress analysis data suggests that adapting dimensions to anticipated load conditions is vital. If the bar is too thin, it may not withstand operational demands.

Properly inspecting dimensions and tolerances can avoid future complications. Many projects experience costly delays due to improper material sizing. Regular audits and checks can help identify potential issues before they escalate. Balancing ideal specifications with practical realities is often a trial and error process. The industry must continuously adapt and refine these parameters for improved outcomes.

Evaluating Surface Finish Options for Aesthetic and Functional Needs

When choosing a stainless hexagon bar, surface finish plays a crucial role. Aesthetic appeal can impact the final product's marketability. Certain finishes offer a shiny appearance, making them suitable for visible parts. For instance, a polished surface can reflect 80% of light. This enhances the visual aspect significantly. However, if the finish is too glossy, it may reveal scratches easily.

Functionally, surface finish can affect performance. For example, a dull, matte finish might provide better resistance to wear. Reports show that certain finishes can increase corrosion resistance by up to 30%. Yet, manufacturers often overlook this aspect. Many focus solely on aesthetics, ignoring how finish impacts longevity.

Choosing the right finish requires careful consideration. Some may prefer smooth surfaces for ease of cleaning. Others might need textured finishes for grip or friction. Evaluating these needs is vital but often neglected. Balancing aesthetics with function is challenging yet necessary for project success.

Considering Cost and Availability in Your Selection Process

Selecting the right stainless hexagon bar for your project involves careful consideration of cost and availability. Prices can fluctuate significantly based on market demand, manufacturing processes, and material source. For instance, some grades might be cheaper but may lack durability. Evaluating the initial cost against long-term performance is crucial. Sometimes, a slightly higher price tag today could save you more in future repairs or replacements.

Availability is another key factor. A material might seem perfect but could be hard to source. Delays in receiving materials can hinder project timelines. It’s essential to check local suppliers and lead times. You might find that certain sizes are more readily available than others. This discrepancy can lead to unexpected challenges. While planning, think about backup options. Are there alternative materials that could meet your needs?

Reflecting on your selection process is vital. Did you prioritize cost over quality? Were there any overlooked supply chain issues? Each project can teach valuable lessons. Reassessing your choices can lead to better decisions in the future. Balancing cost and availability requires ongoing reflection and flexibility in your approach.

How to Choose the Right Stainless Hexagon Bar for Your Project? - Considering Cost and Availability in Your Selection Process

| Dimension (mm) | Material Grade | Cost per kg ($) | Availability (Days) | Common Applications |

|---|---|---|---|---|

| 10 | 304 | 3.50 | 5 | Food Industry, Kitchen Equipment |

| 12 | 316 | 4.00 | 3 | Marine Applications, Pharmaceutical |

| 16 | 430 | 2.80 | 7 | Automotive Components, Architecture |

| 20 | 321 | 4.50 | 10 | High-Temperature Applications, Oil & Gas |