What is Liquid Sulphur Black and Its Uses in Industry?

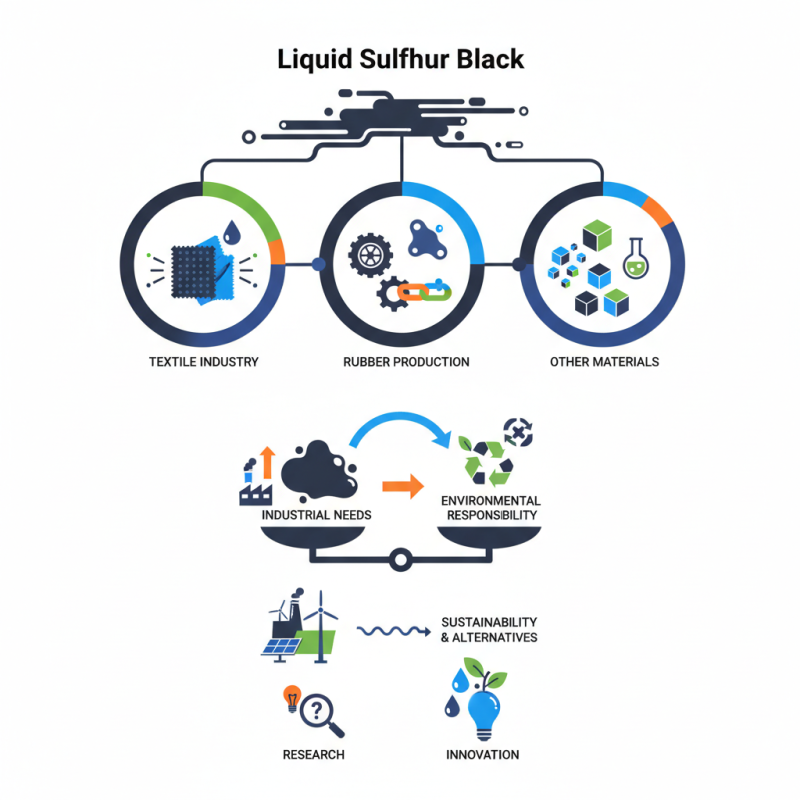

liquid sulphur black is a crucial material in various industrial applications. Renowned expert Dr. Emily Carter states, "Liquid sulphur black transforms processes and enhances product quality." This versatile substance is mainly used in the production of dyes, rubber, and other materials. Its unique properties make it invaluable for manufacturers seeking efficiency and durability.

In the textile industry, liquid sulphur black is favored for its deep color and fastness properties. It allows for vibrant, long-lasting dyes in fabrics. However, while it offers multiple benefits, there are considerations regarding environmental impact. The sourcing and processing of liquid sulphur black raise questions about sustainability.

Many industries rely heavily on this material. But it's essential to reflect on methods to improve its use. Some companies are exploring alternative sources. This shift could minimize the ecological footprint of liquid sulphur black. Balancing industrial needs with environmental responsibility is vital for the future.

What is Liquid Sulphur Black?

Liquid Sulphur Black is a unique industrial product known for its versatile applications. It appears as a thick, viscous liquid, making it distinct from its powder counterpart. This form of sulfur has a rich, deep color, often used to create black dyes and pigments in various industries. It has gained attention for its role in manufacturing rubber, fertilizers, and certain chemicals.

In the textile industry, Liquid Sulphur Black is favored for dyeing fabrics. It penetrates fibers effectively, providing a strong, lasting color. However, some may overlook its environmental impact. The production process can lead to emissions that require careful management. Its use in rubber manufacturing also demands attention. While it enhances durability, the heat and chemical interactions can raise safety concerns.

People often underestimate the complexity of using Liquid Sulphur Black. Proper handling is crucial to ensure safety performance. Many workers lack adequate training about its properties and risks. In this sense, increased awareness is needed. The journey of Liquid Sulphur Black is a reminder of the balance between utility and responsibility in industrial applications.

Chemical Composition and Properties of Liquid Sulphur Black

Liquid Sulphur Black is a fascinating material with unique chemical properties. It mainly consists of liquid elemental sulfur, typically having a purity of around 99%. The chemical structure allows it to combine easily with other compounds. This versatility enhances its use in various industrial applications.

In terms of its properties, Liquid Sulphur Black exhibits low viscosity, making it easy to handle. The material has a relatively low melting point, which allows it to maintain fluidity under certain temperatures. In a report by the Chemical Industry Council, it has been noted that up to 70% of sulfur produced in the industry finds applications in custom formulations, including fertilizers and pesticides. These applications harness the unique qualities of Liquid Sulphur Black to enhance efficiency.

However, handling and storage protocols must be followed meticulously to prevent accidents. Overheating can lead to undesired reactions. Industry publications warn that awareness of proper handling is crucial. Liquid Sulphur Black presents opportunities and risks, and careful thought is needed to maximize its benefits while minimizing hazards.

Industrial Applications of Liquid Sulphur Black

Liquid Sulphur Black is a versatile chemical used in various industries. Its primary application is in the production of dyes and pigments. This substance provides deep black coloration, making it ideal for textiles and leather goods. The ability to disperse evenly in liquids is a key feature. This ensures a consistent color in finished products. Manufacturers appreciate this reliability.

In addition to dyes, Liquid Sulphur Black has significant uses in agriculture. It acts as a soil conditioner. By improving soil quality, it helps increase crop yields. Farmers benefit from its long-lasting effects on plant health. Some might overlook the benefits of soil health. However, it plays a crucial role in sustainable farming. The careful application of this product can lead to healthier ecosystems.

Another important area is rubber production. Liquid Sulphur Black is used as a processing aid. It enhances the properties of rubber, making it more durable. Though it is effective, overuse can cause issues. Striking the right balance is essential for quality. Too much can lead to unwanted side effects in the final product. Industry professionals must monitor usage closely.

Benefits of Using Liquid Sulphur Black in Manufacturing

Liquid Sulphur Black is increasingly gaining traction in various industrial applications. Its unique properties make it a valuable asset in manufacturing processes. One notable benefit is its ability to enhance the quality of products. According to industry studies, using Liquid Sulphur Black can increase the longevity of rubber products by up to 30%, making them more durable in harsh conditions.

In textile manufacturing, Liquid Sulphur Black serves as a superior dyeing agent. It imparts a deep, uniform color to fabrics. Reports indicate that it reduces dye fixation time by 20%. This efficiency leads to lower production costs. Additionally, the environmentally friendly aspects of this compound are noteworthy. Many manufacturers consider it safer compared to traditional dyes, which can contain harmful substances.

However, it's essential to acknowledge potential challenges when using Liquid Sulphur Black. Some manufacturers report difficulties in maintaining consistent quality during large-scale productions. There are instances where improper usage can lead to undesirable color variations. This unpredictability requires rigorous quality control measures. As the industry evolves, addressing these concerns will be vital for wider adoption and trust.

Environmental Impact and Safety Considerations

Liquid Sulphur Black is a chemical compound with various industrial applications. However, its environmental impact raises concerns. In industrial settings, suboptimal practices can lead to spills. These spills may contaminate soil and water, affecting ecosystems. The risk of exposure to workers is also prevalent. Adequate safety measures are crucial to mitigate harmful effects.

Ensuring proper ventilation in workspaces is vital. Personal protective equipment should be mandatory. Yet, adherence to safety protocols often falters. This inconsistency invites potential hazards. Additionally, waste disposal methods for Liquid Sulphur Black require scrutiny. Improper disposal can contribute to environmental degradation. Companies must reflect on their practices and take responsibility.

There is a need for more stringent regulations. Transparency in reporting incidents is essential. Each operator should prioritize sustainable practices. Yet, many still overlook these responsibilities. As concerns grow, the industry must adapt. Balancing usage with safety is challenging, but necessary. It is crucial to foster a culture of safety and environmental awareness.

Liquid Sulphur Black Usage in Various Industries

This bar chart illustrates the usage of Liquid Sulphur Black across various industries. The agriculture sector shows the highest demand followed by the chemical industry and mining. Understanding these usage trends is crucial for assessing environmental impacts and safety considerations.