Position Sensor Tips for Accurate Measurements and Applications?

Position Sensors play a crucial role in various applications, providing accurate measurements that are essential for effective operation. Dr. Emily Carter, a renowned expert in the field, states, "Precision in position sensing leads to breakthroughs in technology." This highlights the importance of accuracy in positioning systems.

Selecting the right position sensor can impact performance significantly. Different types of sensors, such as magnetic, optical, or capacitive, serve unique applications. Each comes with strengths and weaknesses. Sometimes, choices might seem overwhelming. Understanding these differences is vital for achieving optimal results.

Accuracy in measurement must always be prioritized. A common pitfall is neglecting environmental factors that can affect sensor readings. Temperature, humidity, and electromagnetic interference can introduce errors. Rethinking sensor placement and calibration can mitigate these issues. Continuous improvements in position sensor technology remain imperative for modernization. Those who embrace precision will lead their industries.

Understanding Different Types of Position Sensors and Their Functions

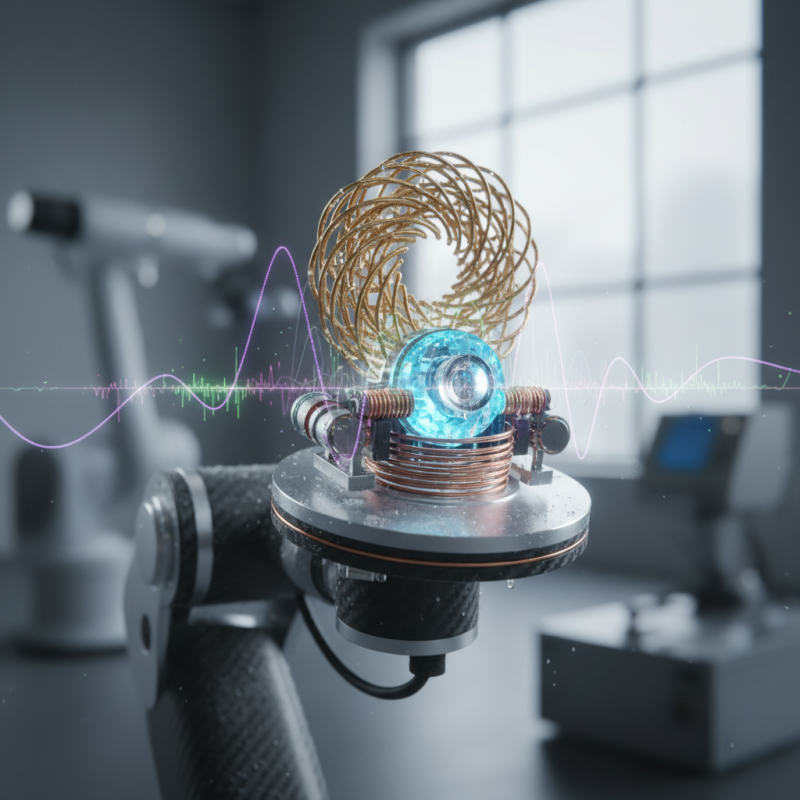

Position sensors play a crucial role in various applications, from robotics to automotive systems. Understanding their types is essential for achieving accurate measurements. Common types include potentiometric, capacitive, and inductive sensors. Each type has unique functions that affect their performance in different environments.

Potentiometric sensors use a resistive element to measure position. They provide a linear response, but can suffer from wear over time. Capacitive sensors, on the other hand, detect changes in capacitance caused by an object’s position. They are often sensitive to environmental factors like temperature and humidity. Inductive sensors operate on electromagnetic principles and are useful in applications where contact is not possible. However, they can be more complex to set up.

In practice, the choice of sensor depends on specific needs. Factors include measurement range, accuracy, and environmental conditions. Sometimes, the selected sensor may not perform as expected, leading to inaccuracies. Reflecting on these challenges can help improve future decisions in sensor selection. Understanding these intricacies ensures that position sensors serve their intended functions effectively.

Factors Affecting Measurement Accuracy in Position Sensors

When it comes to position sensors, measurement accuracy is crucial. Various factors can impact how accurately these devices perform. Environmental conditions play a significant role. Temperature fluctuations can alter sensor readings. Dust and humidity may interfere with sensors, leading to unexpected results. It is essential to maintain a controlled environment for reliable measurements.

Calibration is another critical aspect. Regular calibration ensures that sensors maintain their accuracy over time. Neglecting this can result in cumulative errors. The mounting position also affects performance. If a sensor is misaligned, its readings can be significantly off. Installing sensors correctly can mitigate this issue and improve reliability.

Furthermore, the type of sensor can influence measurement outcomes. Some sensors are more sensitive than others. Their specifications may not cover every application well. Users need to understand the limitations of their chosen technology. Keeping these factors in mind helps create a more accurate measurement setup. However, it's not always perfect, and continuous evaluation is key to improving outcomes.

Calibration Techniques for Optimal Performance of Position Sensors

Calibration is crucial for the accurate performance of position sensors. It ensures that the sensor readings align with actual measurements. Regular calibration helps identify errors that can arise from environmental changes. For instance, temperature fluctuations may affect sensor behavior. If not calibrated, these changes can lead to inaccurate readings.

Using appropriate calibration techniques is essential. A common method involves comparing the sensor's output with a known reference. This can be a physical measurement or a standard gauge. Data from the calibration process highlights discrepancies in measurement. This insight allows for adjustments to be made.

Another technique is to perform linearity checks. This involves testing the sensor at multiple points across its range. It helps spot non-linear behavior that could skew results. Such inspections can be tedious and require a lot of attention. A mistake during calibration can lead to significant measurement errors. Hence, it’s vital to document each step and radially reflect on methods used. Regular review of calibration techniques can promote better practices.

Common Applications of Position Sensors in Various Industries

Position sensors play a crucial role in various industries, ensuring precision in operations. In manufacturing, they monitor the position of robotic arms during assembly. This information is vital for maintaining synchronization and accuracy. Slight misalignments can lead to errors. Ensuring positioning accuracy becomes essential to avoid costly downtime.

In the automotive industry, position sensors contribute significantly to modern vehicles. They are used in steering systems and throttle controls. These sensors enhance safety features by providing real-time feedback. However, their reliability can sometimes be questioned, especially in extreme conditions. Sensor calibration is fundamental, and negligence can lead to severe consequences.

Aerospace is another sector where position sensors are critical. They ensure the accurate positioning of components in aircraft systems. Failures can be catastrophic. Engineers must regularly assess sensor performance. Yet, human error during installation can lead to oversight. Continuous monitoring and adjustments are necessary to maintain optimal functionality. Precision is key in high-stakes environments like aerospace.

Position Sensor Tips for Accurate Measurements and Applications

| Application Area | Sensor Type | Key Benefits | Measurement Range | Typical Accuracy |

|---|---|---|---|---|

| Manufacturing | Potentiometric Sensors | Cost-effective, Simple Integration | 0-100 mm | ±1% |

| Automotive | Magnetic Sensors | High Reliability, Durability | 0-50 mm | ±0.5% |

| Aerospace | Optical Sensors | Precision, Non-contact Measurement | 0-200 mm | ±0.1% |

| Robotics | Capacitive Sensors | High Sensitivity, Fast Response | 0-30 mm | ±0.2% |

| Construction | Laser Sensors | Long Range, Precise Measurements | 0-1000 mm | ±0.3 mm |

Challenges and Solutions in Position Sensor Implementations

Position sensors are essential in various applications, including robotics and automation. However, implementing these sensors can present significant challenges. Environmental factors such as temperature fluctuations and electromagnetic interference can impact accuracy. A report from the International Society of Automation reveals that 30% of sensor malfunctions are due to these external conditions. This highlights a critical need for thoughtful installation.

Calibration is another common obstacle. Many operators underestimate the importance of regular calibration. A study by the National Institute of Standards and Technology indicates that improper calibration can lead to measurement errors exceeding 10%. This can severely affect operational efficiency and safety. Simple mistakes in sensor alignment can also result in incorrect readings.

Designing for redundancy can alleviate some challenges. Implementing multiple sensors in critical applications improves reliability. According to the Sensor Industry Report, systems with redundancy experience 50% fewer failures. However, this can introduce complexity. Deciding when and how to use backups is crucial. Not all situations warrant this added complexity. Users must evaluate if the benefits justify the cost and logistics involved.